Adimec produces multiple lines of cameras designed specifically for high quality, repeatable Display Inspection. Each camera has specialized features making them ideal for this task. These include high resolution combined with a high fps, image uniformity optimizations, precision sensor alignment, high sensor sensitivity, CoaXPress interface and more. In this blog we’ll go over these features in more detail and explore why they help make Adimec cameras ideal for Display Inspection.

High resolution and framerate

One of the key features that makes Adimec’s cameras well suited for display inspection is high resolution combined with an achievable high framerate. High resolution is required for detailed display inspection, especially in DE-MURA detection and color uniformity measurements, as each display pixel requires multiple camera pixels. The ratio of display resolution to inspection camera resolution should be at least 1:3; which means a full HD (1920 x 1080) display should have a minimum camera inspection resolution of 5760 x 3240 pixels. Adimec has 2 cameras matching these requirements: the S-50A30 with 8000 x 6000 pixels and the S-65A35 with 9300 x 7000 pixels.

Versatility of CoaXPress cables

With the exception of the GigEVision D-12A09, all of these cameras run over CoaXPress cables. These cables provide multiple benefits for display inspection including high data speeds, lightweight cables over longer distance, and power over cables, rather than having to use a separate PSU. The physical cables themselves allow for more versatility when implementing the cameras to a display inspection system. They are lightweight and flexible, and the lack of a separate power source leaves less cables to deal with. The high data speed these cables offer allows for a higher framerate, leading to faster inspections and an increased throughput.

Specialized camera features

Adimec’s machine vision cameras also have specialized features that allow them to perform uniform, accurate display inspection. Low Frequency Flat Field Correction (LF FFC) compensates for non-uniform lighting and creates a flat image for uniform imaging. It also corrects for lens artifacts and vignetting, allowing for the image quality needed for inspection. A newer specialized feature for display inspection is multi-exposure mode. When inspecting an active display, is a camera exposure time is less than the display refresh period, stripes or “bands” appear on this display. This is known as banding which negatively affects an inspection because it makes the resulting image nonuniformity. Multi-exposure mode compensates for this banding effect by taking multiple exposures of shorter integration times and combines them to create a band-free image.

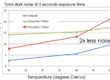

These two features lead to better (DE)-MURA detection, as a uniform image is required for accurate inspection and detection. The non-uniformity of the camera image (including pixel blemishes), performance variations due to test conditions (like temperature variations, sensor speed, etc.), and camera-to-camera variations should be minimized. These camera corrections are done in dark and bright to increase uniformity, as pixels act differently in different light settings. All cameras are tested for pixel blemishes according to the input from the sensor manufacturer and as an Adimec standard, these pixels are compensated inside the camera. To detect Mura in dark, camera integ

ration times of seconds are required. With very low power consumption and perfect thermal drain between the image sensor and the application, Adimec cameras are also optimized to achieve the lowest noise for MURA inspection.

Precision sensor alignment

Adimec’s precision sensor alignment in all 6 degrees of freedom provides a superior flat image over the entire field of view and minimizes if not eliminates camera to lens adjustment requirements. The precision alignment of the sensor relative to the mounting datum is critical to having an image that is sharp over the entire field of view. Adimec’s proprietary alignment stations (as shown to the right) ensure that each sensor is precisely aligned in all 6 degrees of freedom for tool matching and a true accurate image. Extremely consistent alignment is achieved camera to camera for excellent copy exact performance and camera interchangeability.

High sensitivity and Display Inspection

Lastly, high sensitivity is a very important aspect of display inspection. To achieve this high sensitivity, low noise levels, dark current and high Quantum Efficiency are all required. Higher quantum efficiency across the visible spectrum means improved sensitivity for the sensor. As latest display technologies can exhibit deep black levels, low contrast MURA effects are much more noticeable. A very sensitive camera with low noise levels at long exposure times is important for dark Mura inspection. For bright Mura and color uniformity measurements, both camera SNR performance and linear pixel response are essential. Latest CMOS image sensor technologies are better in sensitivity and outperform previously used CCD technologies in display inspection applications.

For more information on Adimec cameras for display inspection, contact us.

English

English 日本語

日本語 简体中文

简体中文