Temperature plays an important role in camera performance. Therefore, Adimec always designs efficient, low-power cameras that can be passively cooled via the camera housing. With the D-103A12-T01, Adimec has created a camera that is actively cooled using a thermoelectric cooler (TEC) and fan. This camera was designed specifically for display inspection systems. The integrated cooling helps the camera maintain a stable image uniformity, as well as reliability in a fluctuating environmental temperature when working at long exposure times. This blog will explain why this is important.

Dark current and DSNU

As the latest display technologies can exhibit deep black levels, low-contrast Mura effects (display defects) are much more noticeable. Therefore, a very sensitive camera with low noise levels at long exposure times is required to perform dark Mura inspection.

Two important sensor performance characteristics that influence the camera sensitivity are dark current and dark signal non-uniformity (DSNU). Both are heavily influenced by temperature. Dark current is the electric current that flows through the image sensor even when no photons enter the sensor. It is a thermal phenomenon, as the amount of electrons generated depends on the image sensor temperature. These electrons are added to the signal output, as the image sensor cannot differentiate between the electrons converted from photons and those generated by the dark current. This results in decreased sensitivity in dark field conditions. Bright field measurements are less affected by dark current.

The dark current (specified as e–/s) also depends on the exposure time. Applications, including display inspection systems, typically require the use of long exposure times (in the order of seconds). The dark current will have a greater effect on these types of measurements, compared to applications that use very short exposure times. Limiting the exposure time to reduce the dark current is not an option in these long-exposure imaging applications. But a possible solution is cooling the image sensor, which actively results in less dark current. A good rule of thumb is that every 5 – 9 ˚C that the sensor is cooled, the dark current halves.

The dark current is often calculated as an averaged value for the entire image sensor. In reality, it will vary across the sensor, with each pixel having its own dark current. This, in combination with the fact that not all pixels are identical, results in a variance of the electrons measured when the sensor is not exposed to light. The variation in dark current thus contributes to the so-called Dark Signal Non-Uniformity (DSNU). DSNU is an important parameter in display inspection systems: the point is to measure the display defects, not the uniformity of the image sensor itself. As the dark current decreases with a lower image sensor temperature, so will the DSNU value.

Nowadays, the absolute value of the dark current in CMOS sensors does not necessarily cause challenges by itself. Sensors with low dark current can be fabricated. The reason for using a thermally stabilized camera is more important for having a stable noise contribution. This means that the TEC does not necessarily need to cool the sensor, but rather keep it at a fixed temperature.

TEC

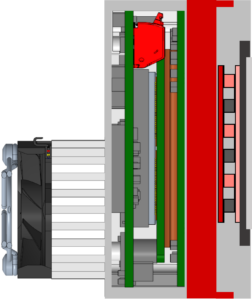

The DIAMOND D-103A12-T01 camera uses a TEC and fan to actively cool the image sensor. The TEC is added between the image sensor and the camera housing (see Figure 1). A heatsink with fan is integrated on the backside of the camera. This results in the ability to control the image sensor temperature from +20 °C to +55 °C, at ambient temperature conditions from +10 °C to +45 °C.

Figure 1 Section view of the D-103A12-T

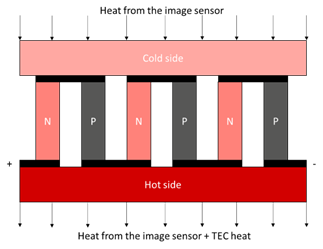

A TEC is a relatively small component that can remove heat from the image sensor more efficiently than a heatsink. It uses semiconductors to transfer heat from one side of the TEC to the other. A schematic cross-section of a TEC can be seen in Figure 2. It is an active component that can both heat and cool. Therefore, in addition to efficiently removing heat, it can also regulate the temperature to a fixed value — for example, by using a PID control.

Figure 2 Cross section of a thermoelectric cooler

The thermoelectric cooler combines N- and P-type semiconductor materials to generate a cold side that absorbs heat. When a charge passes through the semiconductor couples, all electrons accumulate at the hot side of the TEC. Moving electrons collide with each other, which generates heat. At the cold side of the TEC, less electrons are present, so a lower temperature is achieved at this side. The cooling of the TEC can be controlled very accurately by varying the current through this element, because an increase in current means more electrons move to the hot side of the TEC. Reversing the current basically flips the hot and cold side of the TEC.

In the D-103A12-T01, the cold side of the TEC is placed directly onto the image sensor. Since heat always flows from hot to cold, an active heat flow is generated to cool the sensor. However, the current required to generate a hot and cold side adds extra heat to the process via electrical heating. Therefore, the hot side of the TEC puts out the heat from the image sensor, plus the heat that is generated during the cooling process. The extra heat at the hot side is conducted via a heatsink to the camera’s housing, which is actively cooled with a fan.

EMVA measurements

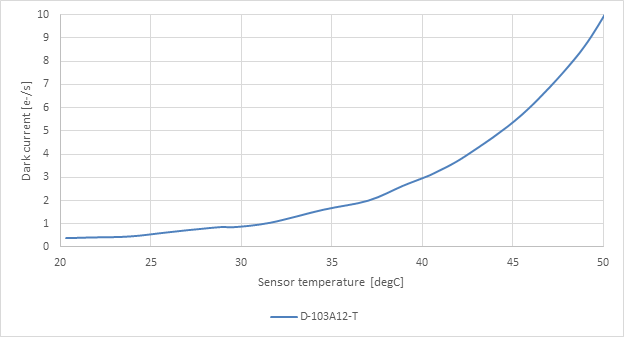

We performed multiple EMVA1288 measurements to determine the dark current of the D-103A12-T01 at different image sensor temperatures. The results are summarized in Figure 3.

Figure 3 Dark current against the sensor temperature for the D-103A12-T

The dark current rises exponentially with an increase in the sensor temperature. It is very advantageous to cool the sensor to between 20 ˚C and 35 ˚C, because the dark current is still less than 2 e-/s. When the sensor temperature is between 40 ˚C and 50 ˚C, it can be up to 10 e-/s. So, at 50 ˚C, the image sensor will generate 9 additional electrons per second compared to at 30 ˚C. This is equivalent to 4 DN12/s of video level. Therefore, in display inspection systems that use exposure times of multiple seconds, this difference in image sensor temperature can have significant effects on the sensitivity of the camera.

Using a TEC is not only useful for cooling the sensor — it also results in a smaller temperature gradient across the sensor. Temperature gradients result in varying dark currents across the sensor, resulting in dark signal non-uniformities. We also measured the DSNU at different sensor temperatures using the EMVA1288 (see table 1). The controlled sensor temperature decreases the DSNU and eliminates the effect of ambient temperature fluctuations on the camera performance. However, since dark current is the one of the main components of DSNU, the exposure time also has a great effect as can be seen in table 1.

| Temperature | Exposure time | DSNU |

| [˚C] | [ms] | [DN12] |

| 20 | 20 | 2.3 |

| 50 | 20 | 2.6 |

| 20 | 1000 | 2.9 |

| 50 | 1000 | 9.2 |

Tabel 1 DSNU values at different temperatures and exposure times

When the exposure time is set to 20 ms, the difference in sensor temperature does not have a big effect on the DSNU value. However, when the exposure time is increased from 20 ms to 1000 ms, the DSNU value at 50 ˚C sensor temperature increases from 2.6 to 9.2 DN12. If the image sensor is cooled to 20 ˚C, the DNSU decreases from 9.2 to 2.9 DN12 at 1000 ms. Due to the typical long exposure time required when inspecting displays, cooling the sensor will give a great advantage in the image quality.

Conclusion

Actively cooling the image sensor will increase the image quality through a decrease in dark current and DSNU. It also keeps the image sensor at a steady temperature due to the quick and precise control that a TEC offers. This increases the image-to-image repeatability. These uniformity benefits are especially useful in dark Mura display inspection and display pixel calibration. But these are only part of the full picture: the D-103A12-T can improve the uniformity even further using advanced pixel-based uniformity correction algorithms, which you can read more about here.

English

English 日本語

日本語 简体中文

简体中文