The Importance of Full Well Capacity

At first glance, it may not be obvious how the full well capacity of a camera’s sensor can affect your measurement.

The digital video level is determined by the product of light intensity and exposure time. This is often referred to simply as “the exposure.” The sensor characteristics that influence how long the exposure needs to be to reach a certain digital level are the quantum efficiency and the full well capacity.

There are many applications in which the amount of light and the exposure time are not critical factors: they can be adjusted to reach the desired exposure. From this perspective, it seems that with only some exceptions, the full well is not especially important.

Shot Noise

However, there is another physical phenomenon that may make the full well capacity a bit more important than you might initially think — shot noise.

The source of shot noise is related to the particular nature of light. It is proportional to the square root of your signal (or, in other words, the light entering the camera) in electrons. This means that although the shot noise increases with the signal, its relative contribution reduces.

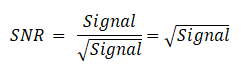

In shot noise dominated applications, the signal-to-noise ratio (SNR) is determined by the ratio between your signal and the shot noise:

This formula shows that the higher the signal, the better the SNR. As the full well capacity of a sensor limits the maximum signal, a sensor with a higher full well will give you a better SNR.

Comparing Three Sensors

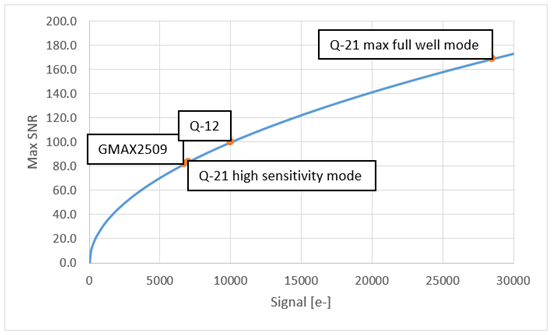

In this blog series, we compare the Q-12 (CMV12k), the Q-21 (GSPRINT4521) and the GMAX2509 sensor. The GMAX2509 has a similar pixel design and similar characteristics to the GMAX0505, a sensor that is more often compared to the GSPRINT4521. One place where those sensors vary most is in their available maximum full well.

With the Q-21 (GSPRINT4521), you can configure the sensor to get a maximum full well from about 7.0k to 33.6k electrons. Here, we focus on both the maximum full well and the high sensitivity configurations. The high sensitivity configuration has the lowest full well capacity.

With the GMAX2509 you can configure the sensor to get a maximum full well from about 2.5k to 6.7k electrons. Here we only focus on the maximum full well configuration.

The maximum full well for the Q-12 is about 10k electrons, which is its only possible configuration.

When we calculate the theoretical maximum SNR based on the specified maximum full well and the earlier mentioned equation, we would get the result indicated in the graph below:

Variables in Available Full Well

To understand how there can be this large of a difference in the available full well, we must look at the pixel design. Although we will see that the production method can also have an influence, in this case, the main reason for the higher full well of the Q-21 vs the GMAX2509 is the pixel size.

The full well is the number of electrons that fit into a single pixel — so there is simply more space for electrons in larger pixels. In this case, the difference in pixel size is 4.5um square in the Q21 vs 2.5um square in the GMAX2509. Here’s a quick calculation: The surface area for the 4.5um pixel is larger by a factor of 4.5^2/2.5^2 = 3.24um.

If we multiply this factor by the maximum full well of the GMAX2509, we can calculate the hypothetical full well capacity if the GMAX2509 had the same pixel surface area as the Q-21. So, starting from 6.7k electrons (the maximum full well for the GMAX2509) and multiplying by 3.24, we get 21.7k electrons. This is still less than the specified maximum full well of 33.6k electrons for the Q-21. The discrepancy is most likely explained by a difference in manufacturing technology and a lower fill factor in terms of the active part of each pixel.

This is only one of many variables that Adimec considers when determining which sensors will ensure peak performance in the specialized applications of our customers.

English

English 日本語

日本語 简体中文

简体中文