Despite the challenges of the global pandemic and resulting economic downturn, the worldwide demand for chips continues to increase, the industry’s growth is expected to continue into 2022. IDC (International Data Corporation) predicts the semiconductor market will reach $600 billion by 2025. With the rise in demand for semiconductors, the use of in-line inspection and metrology systems will also grow.

The increasing demand at the start of the pandemic shifted toward the masses forced to spend much more time at home. Whether working or playing, the need for computers, gaming consoles, smart phones and other essential devices suddenly soared. Semiconductors for cars were initially on the decline as traveling and commuting rapidly waned. But that need bounced back more quickly than expected, as companies struggled to keep up with chip demand. Which explains many recent rental car shortages, and some consumers getting slapped with a 15K upcharge on the MSRP of new vehicles.

There has been a shift with more and more companies “going remote” and many brick-and-mortar businesses moving to online platforms as a result of the pandemic. We have also been relying heavily overall on electronics for our entertainment needs and social connection. Therefore, the uptick in the demand for electronics is expected to continue into next year and beyond.

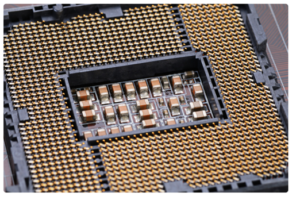

Semiconductor and electronics manufacturers have rushed to increase capacity, maximize yield, and increase throughput to push more components out to meet this ever-growing need. This resulted in a large increase in demand for in-line inspection and metrology systems to provide 100% analysis at a high precision while maintaining high throughput.

Image sensor manufacturers such as AMS, Sony, Gpixel and ON Semi and subsequent camera manufacturers have had to ramp quickly to support the growth in inspection systems. Machine Vision manufacturers in general have struggled with increasing component and supply bottlenecks while also facing higher demand which puts them in a holding pattern. This cycle of needing more to produce more while also facing shortages has been an interesting dynamic, but most in the industry have continued diligently to meet this challenge.

The latest ultra-high-resolution image sensors such as the Gpixel GMAX3265 and the Vita25k from ON Semi and the cameras using these sensors, provide repeatable uniform images, high sensitivity, and the fast frame rates necessary to meet these inspection challenges for semiconductors and electronics.

To explore these topics further

For more on increasing throughput in semiconductor and electronic inspection, please review this article.

Check out this Financial Express article for more on recent Semiconductor Industry growth, key growth drivers, and changing trends.

This A3 Association for Advanced Automation article covers 2021 Machine Vision market trends in more detail.

Please contact your local Adimec business office for more information on Adimec cameras.

English

English 日本語

日本語 简体中文

简体中文