Boresight has long been a chore in optical systems. Boresight is the process of co-aligning the optical center line of the optical elements and devices. Typically, boresight is accomplished with mirrors or prisms that are moved to align the different optical elements and devices. Each of these alignments cost time and money in development and manufacturing, not to mention the reliability risk of having moving parts, even if they are staked with epoxy, after boresight/alignment. That is how mechanical boresight works. Electronic boresight moves the field of view on a camera sensor which minimizes or eliminates the need for those mechanical adjustments. Adimec’s new TMX-53 and TMX-55 cameras have improved electronic boresight capabilities that allow mechanical boresight adjustments to be minimized. When the camera sensor is precision aligned to the camera mounting surface, and the camera has an electronic crosshair capable of moving 100’s of pixels, electronic boresight is easy.

Previously cameras of this type had a maximum boresight capability of +/- 20 pixels. This allows for a degree of electronic adjustment but not sufficient for the elimination of a mechanical boresight adjustment in many situations.

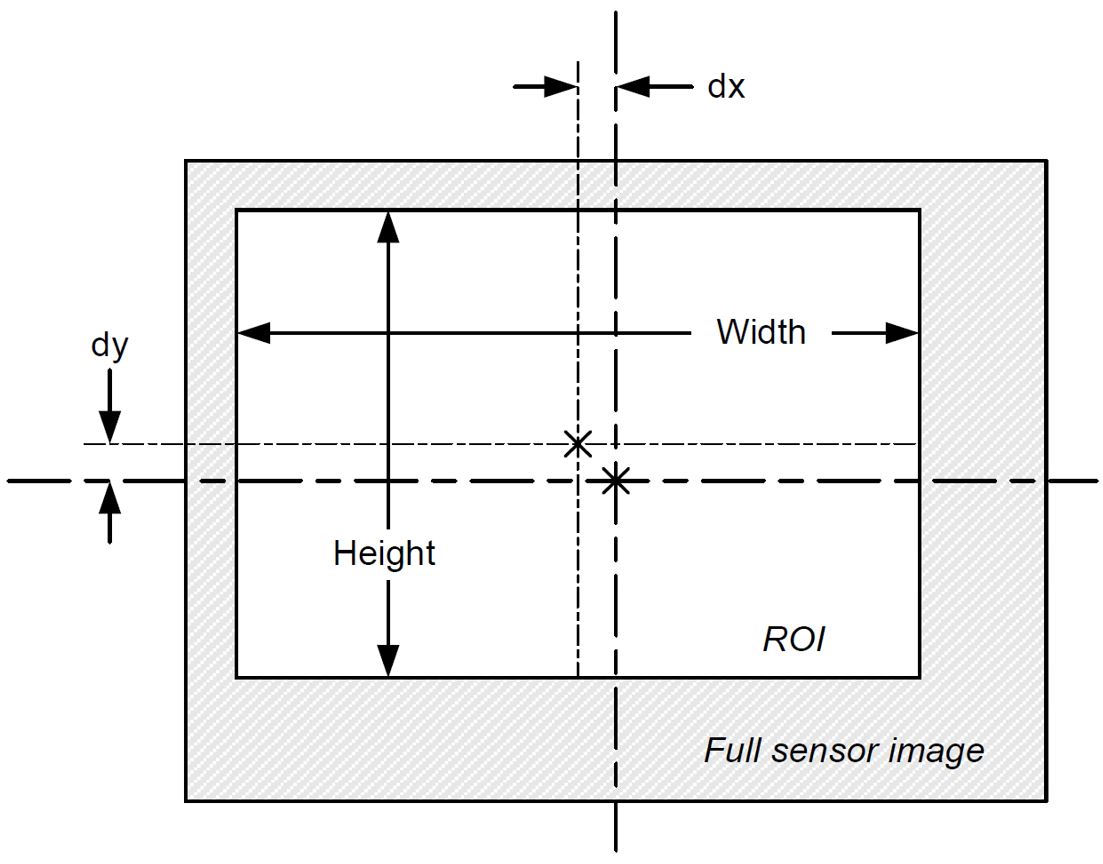

Adimec cameras are all aligned with six degrees of freedom precision. The alignment tools look like the one shown in the figure below. This precision alignment allows for many systems to accept cameras with no boresight required. However, in outdoor systems, the complexity factor can be quite high. This often requires boresighting the camera to the optics. Adimec cameras have an electronic reticle that is a two-pixel wide cross-hair, as shown in the figure below. This cross-hair is controlled through software or the GUI and can either track as the region of interest or move as the cross-hair is commanded to move. The full resolution for the TMX-53 is 4096 x 3008 and for the TMX-55 is 4096 x 2176. At full resolution the boresight capability is only 16 pixels in x, because there are only a few additional pixels outside that full sensor area. However, most applications do not utilize the full resolution and a region of interest (ROI) of say Full HD, 1920 x 1080 (Width x Height), is required to match the output of the monitor. At this output resolution the boresight adjustment is 100’s of pixels. That Region of interest can be centered in the sensor full image or can be shifted (dx, dy) and the boresight set to track the movement of the ROI.

Adimec cameras have an electronic reticle that is a two-pixel wide cross-hair, as shown in the figure below. This cross-hair is controlled through software or the GUI and can either track as the region of interest or move as the cross-hair is commanded to move. The full resolution for the TMX-53 is 4096 x 3008 and for the TMX-55 is 4096 x 2176. At full resolution the boresight capability is only 16 pixels in x, because there are only a few additional pixels outside that full sensor area. However, most applications do not utilize the full resolution and a region of interest (ROI) of say Full HD, 1920 x 1080 (Width x Height), is required to match the output of the monitor. At this output resolution the boresight adjustment is 100’s of pixels. That Region of interest can be centered in the sensor full image or can be shifted (dx, dy) and the boresight set to track the movement of the ROI.

The TMX-53/55 cameras have a new video pipeline that not only provides full color processing and adaptive resolution but also sensor level boresighting that can be changed on the fly. That is, it can be changed in real time. In the above case of a full HD output it can be moved +/- hundreds of pixels. There are many cases to completely cover this subject such as that the ROI can not move off the full sensor image at any border. However, the key here is that for reasonable sized outputs the range of boresight adjustment is hundreds of pixels, potentially opening up a design space for the system architect that eliminates the need for alignment of the camera to the optical axis. Boresight can be accomplished electronically.

Click on the names of the cameras for more information on the TMX-53 and TMX-55, the next generation in global security cameras.

English

English 日本語

日本語 简体中文

简体中文