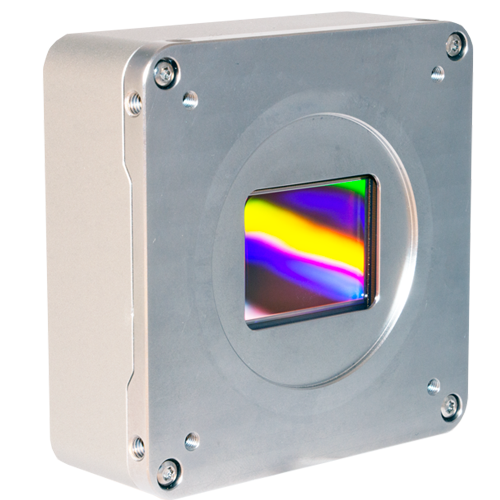

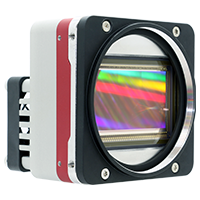

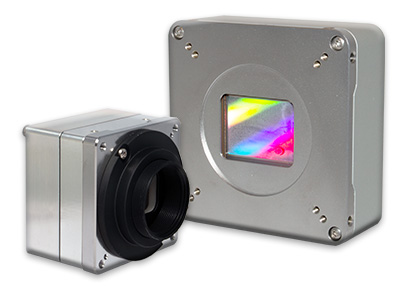

CAMERAS FOR DISPLAY INSPECTION SYSTEMS

Cameras for display inspection systems

In the display manufacturing process, advanced inspection technology is crucial to ensure high quality output and enhance production yield. With increasing demand for displays to show greater contrast in various lighting conditions and the need to inspect and calibrate every pixel, display makers face complex challenges while also keeping inspection costs reasonable.

Adimec provides high-resolution innovative cameras to meet these display challenges. Typical applications include in-line optical inspection for display-module calibration and device inspection

Automated Inspection of Active Displays

with Increased Resolution

The quality of each display pixel of OLED and MicroLED displays needs to be both inspected and calibrated. Adimec cameras are well suited for inspecting these ultra-high definition displays. They offer increased sensitivity, wider dynamic range and the ability to measure with very low contrast and deep color.

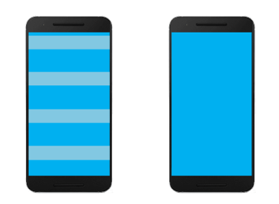

Inspection Uniformity Needs

With new displays showing increasing contrast and enhanced performance in varied lighting, there are greater inspection challenges in both demura (bright) and dark conditions. Adimec cameras respond with increased sensitivity over existing sensor technologies, combined with advanced uniformity correction algorithms. A clean accurate image is generated to inspect the dark display. Bright display inspection needs are met with Flat Field Correction and Multi-exposure technology.

Maximum Display Performance at Acceptable Cost

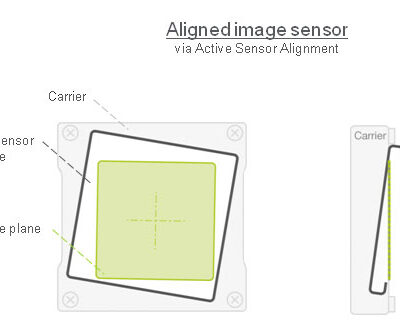

Even with OLED and MicroLED inspection challenges becoming more complex, the cost to inspect and calibrate must be considered. Faster data transfer speeds make display manufacturing more efficient than ever. Precise image-sensor mounting and alignment allows customer to reduce mechanical and optical alignment time. Adimec cameras provide a combination of high throughput, higher quantum efficiency, and optimized uniformity calibrations at an attractive cost.

English

English 日本語

日本語 简体中文

简体中文