Adimec is introducing a new 50-megapixel camera the S-50A30 based on the CMOSIS CMV50000. The new camera provides more than just higher resolution. This CMOS camera, provides inspection accuracy increases, the highest inspection throughput at 50 Mpx, and the next step in image quality.

This is a three-part series that illustrates why to choose a 50 Mpx camera. We will compare to 25 Mpx cameras and high-resolution CCD cameras. In part one we discussed the inspection accuracy increases including a 20% square resolution increase along with a doubling in total resolution compared to a square 25 Mpx sensor (e.g. S-25A70/80), stellar image uniformity, and a sharp image over the entire Field of View (FOV).

In part two we discuss inspection throughput improvements at 50 Mpx including >4x higher inspection throughput compared to CCD image sensors; increased throughput with less movement steps via increased field of view; and how Adimec Connect & GrabTM ensures a fast and easy system integration with the stable high-speed CoaXPress interface.

Finally, in part three we discuss the CMV50000 as the next step in image quality, exemplified by improved sensitivity, being ideal for darkfield, brightfield and phase shift metrology applications as well as an example showing its readiness for display inspection applications.

Inspection Throughput

50 Mpx CMOS vs 50 Mpx CCD: CMOS is >4 Times Faster at less than half the cost

The highest speed of any camera in the resolution space with increased throughput due to increased field of view (FOV) makes the S-50A30 the leader in throughput.

The CMV50000 sensor in the S-50A30 is >4x faster than CCD image sensors in the >50 Mpx space at less than half the cost. Consider the table below showing the CMV50k compared to three high resolution CCD image sensors and you see a huge increase in speed.

| Sensor | CMV50000 | KAI-47051 | CHR70M | 120M |

| Manufacturer | AMS CMOSIS | ON Semi | AMS CMOSIS | Canon |

| Resolution | 7920 x 6004 | 8856 x 5280 | 10000 x 7096 | 13280 x 9184 |

| Mpx | 47,5 | 46,8 | 71,0 | 122,0 |

| Shutter type | Global | Global | Rolling | Rolling |

| Maximum frame rate | 30,9 | 7,0 | 3,0 | 9,4 |

Increase Throughput with Less Movement Steps

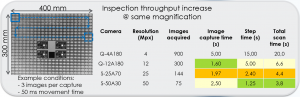

Compared to 25 Mpx there is an increase in throughput with less movement steps due to the increase in Field of View with the 50 Mpx sensor which allows more of the item under test to be imaged, be that area or number of components. Even with its rather slow frame rate relative to lower resolution machine vision cameras the increased resolution leads to a much larger field of view that results in the S-50A30 being the winner in the throughput race as shown in the following graphic and table.

Improved Resolution at Constant Field of View

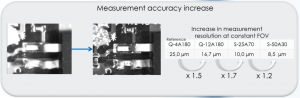

The S-50A30 also gives improved resolution at constant FOV as shown in the example below (left) which compares a 25 Mpx camera (left image) to the S-50A30 (right image). The table graphic to the left shows the increase in measurement resolution for constant field of view.

Adimec Connect & GrabTM

Technically not related to camera throughput but related to throughput of your design team is that the S-50A30 will also support short system development times and short time to market due to low cable complexity, easy Adimec Connect & GrabTM experience and optimized true accurate image. This approach allows imaging engineers to focus on system development and simplifies single and multi-camera vision applications.

Summary

Again, we have shown that the S-50A30 provides more than just higher resolution. Speed cost, throughput and Adimec Connect & Grab all make this camera a stellar choice for machine vision applications. In part three we will show further examples of image quality improvement including its suitability for 2D and 3D metrology, improved sensitivity and an example of its applicability to display inspection.

日本語

日本語 English

English 简体中文

简体中文