Adimec Connect & GrabTM wraps the whole digital imaging implementation process into a quick and easy package that allows quick and easy single or multiple camera integration. Typical time to start evaluating the first images is less than one hour.

The connect & grab experience is twofold.

Connect

One part of the experience is related to communication and/or interface (connect). It is easy to get a camera working in combination with all necessary components in an imaging system. Adimec achieves this by validating our camera with a large selection of components, like cables and frame grabbers. We validate in test conditions matching those of our customers.

Combined with the easiness of GenICam, which is part of the CoaXPress standard, this first aspect of Adimec Connect & Grab reduces the time required for setting up the communication with the camera. This allows vision engineers to start directly with testing and integrating the camera in the vision tool instead of having to spend time on the interplay between camera, cable and frame grabber.

& Grab

The second part of the experience is related to the image quality: clean raw images are provided (Grab) out of the box. For calibrations that can only be done on system level, Adimec’s feature set makes it easy to get the job done within minutes.

Adimec Connect & Grab is thus designed to reduce the time spent by the engineer at the early stage of evaluation and design-in. The easy interfacing, the clean, raw image and the similar feature set between cameras make Connect & Grab cameras very suitable for multi camera vision systems. The aspects of Adimec Connect & Grab are designed to reduce the effort of combining a high resolution camera with multiple low resolution cameras in a single system.

How Adimec Connect & Grab is put into practice

Example 1: NORITE Xperience Package

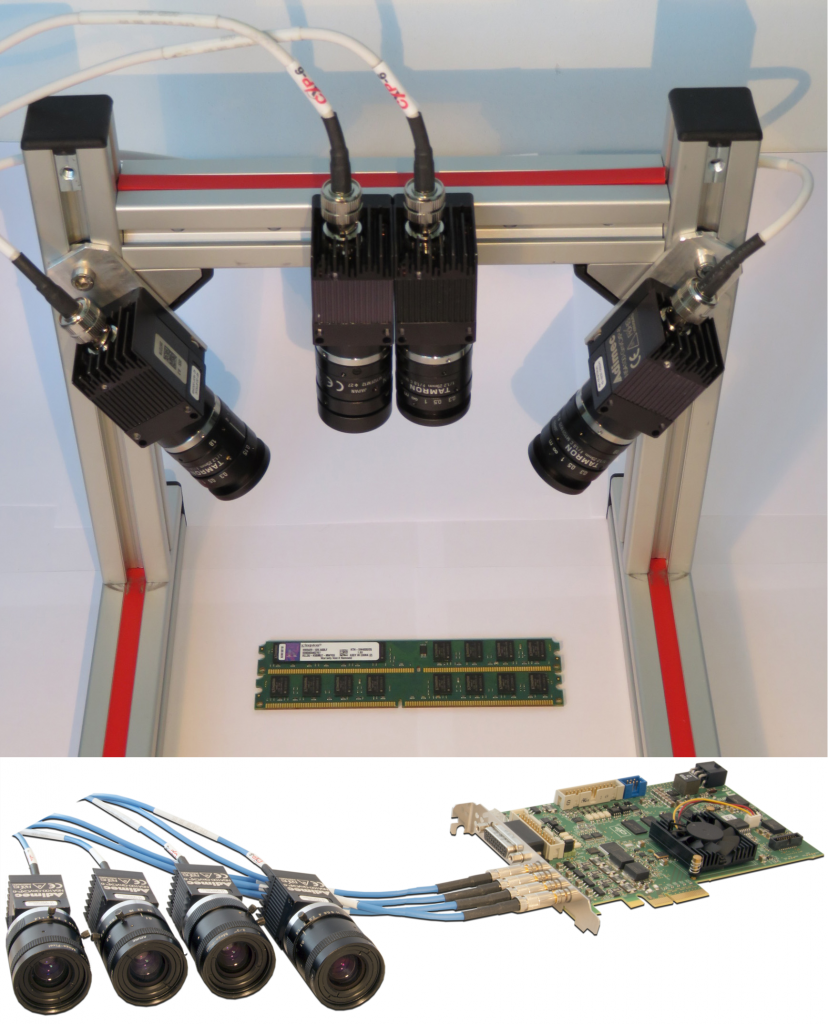

Together with frame grabber and cable suppliers, Adimec created a well-tested and documented package for a multiple camera solution. On customer request, Adimec can provide a development kit combining all vision components to give a quick start to your development. Download the NORITE Xperience Package leaflet for more information.

The Adimec NORITE Xperience Package: 4 cameras, a frame grabber and the necessary cables.

Example 2: Adimec Camera Features

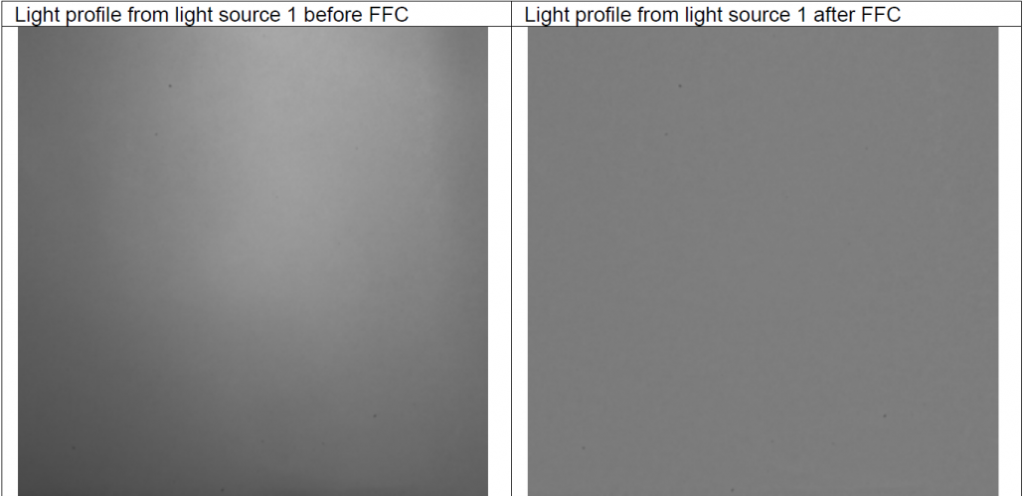

Corrections that can be done at the factory are performed at the factory. However some corrections require calibration in the field. One such calibration is the low frequency flat field correction (LF-FFC). Our camera offers an easy interface to perform the low frequency flat field correction within minutes. If for some reason the interface is not clear, our application notes will help you through the calibration process. Download the low frequency flat field application note for more information.

Left image shows darkening at corners – uncorrected, Right image shows LF-FFC and a resultant beautiful uniform image.

Example 3: Clean, raw image out of the box

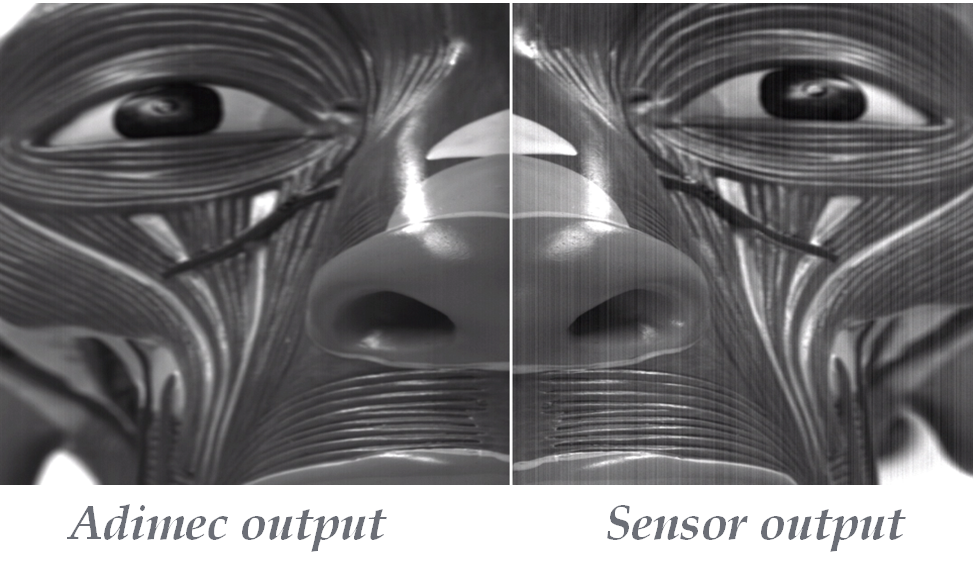

Excluding the calibrations that can only be done on system level, Adimec cameras offer a clean raw image out of the box. This means the camera has undergone dark and bright field (column) corrections. Furthermore defect pixels are detected, added to a defect pixel list, and corrected for during live acquisition. These calibrations all contribute to an image that can directly be used in the application.

Right image: the image as obtained from the sensor without any corrections. Especially the column to column noise is clearly visible. Left image: the image obtained from an Adimec camera after corrections have been applied.

日本語

日本語 English

English 简体中文

简体中文